Petra

Petra was created as a collaboration between myself and three other designers. We were tasked with designing and manufacturing ten identical stools using steel rod and one other material of choice. All ten stools were then sold at a student organized design show.

Steel

Design constraints stated that steel would be used as the legs and support of the stool. The various restrictions of working with this material quickly became apparent, most notably the difficulty in working such an unforgiving material. However, the benefits of strength and minimalism outweighed the disadvantages.

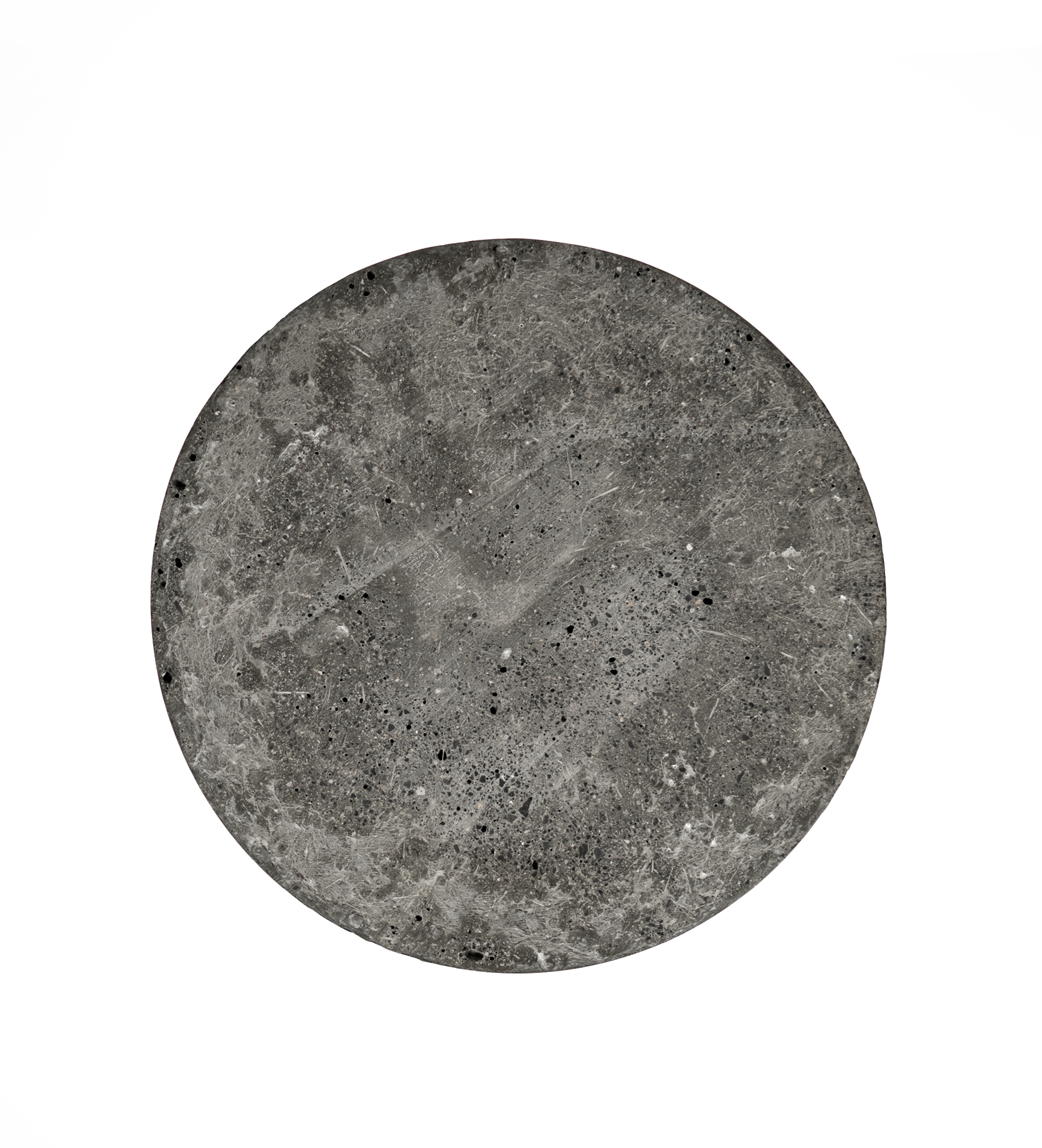

Concrete

We knew we wanted our second material to be one that was removed from its natural setting and used in a way that was unconventional. Concrete is classically rough, unfinished, and boring. We believed it had more potential than this. It can be elevated to something refined, smooth, and surprisingly elegant.

Exploration

Explorations first began in small scale wire. We wanted to focus on coming to understand the bending process and how metal reacts to a bend. As we moved on to 5/8” rod it became apparent that we needed to pursue a metal form that was minimal in design yet elegant in form. Through our concrete explorations, we developed a mixture that was both strong and lightweight. We also tested different casting forms and processes, quickly determining which would best suit our purpose.

Production

Production of identical stools required that we develop a system of manufacturing. Fixtures were made to ensure proper bends and welding of the steel base. Vacuum-formed plastic was then used to create identical molds for the concrete.

Final Form

Our explorations lead us to a powder-coated steel base of triangles and an inverse cone of concrete for the top. I personally refined the steel’s geometry and shaped the final concrete form to complement the angles found in the base.

Exhibit

The project concluded with a design exhibition where the stools were displayed and put up for sale. We sold all ten stools.